DIAMOND CERAMIC COATING ON AUTOMOBILES

What is it?

One of the most important factors in

maintenance of a car is the exterior look of the car, especially its paint’s

shine and gleam. Diamond ceramic coatings impart a color enhancing gloss to the

exterior surface and simultaneously protect it from UV rays, chemicals and

extreme heat.

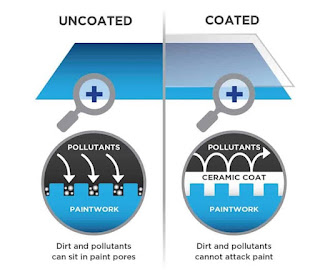

There are three coats on the surface

of a car, innermost is the primer, middle one is a base coat of paint and an

outermost clear coat. DIAMOND ceramic coating is applied on the top of clear

coat. It’s a very thin coating and it is completely invisible to the naked eye.

The diamond coating covers the car in

a shell of protection and protects from exterior damage. It enhances the color

and look of the car. Diamond makes the car exterior surface to shine more

stronger. The coat forms a semi-permanent bond with the surface of the car, so

that the coat does not wash away or break down easily over a short period of

time and lasts for years. It blends with the paint of your car and creates

additional hydrophobic (water repellent) protection layer. Nowadays many big

automobile brands are using this type of ceramic coatings.

Working of the

ceramic coating:

Coating

are carefully applied by certified applicator’s as a liquid one panel at a time

covering the exterior painted surfaces. The paintwork is firstly decontaminated

and prepared to ensure the coating achieves a good bond to the paintwork.

The

principle differences are the amount of SiO2 content in the product.

Some have levels as low as 5% as typically found in maintenance sprays. Others

have as much as 70%. As a general rule the higher the level of SiO2

the more durable the product will be.

Diamonds as well as graphite are crystallographic forms of carbon. Difference between these forms is the electronic configuration (sp3 for diamond and sp2 for graphite) [02] leading to different crystallographic networks and physical properties. Diamond has a hexahedral network which leads to the formation of four covalent links responsible for the high hardness of this material. Diamond deposition on tools is a Chemical Vapour Deposition process (CVD) at low pressure of around 35 Torr and relatively low temperature around 800°C performed in batches. Adding different gases during deposition to enhance nucleation [03] or saturating surface in carbon before diamond deposition [04] gives several ways to improve the process. Carbon source is methane (CH4) and chemical reactions are occurring due to pressure and temperature conditions, leading to deposition of the diamond layer.

Main

obstacle to diamond deposition:

Unfortunately,

if diamond layer resists to abrasive wear, other problems are induced by the

deposition process due to coating / substrate compatibility. Most common

material for machining tool is tungsten carbide bound by cobalt. It exhibits a

high hardness, due to tungsten carbide, but also a sufficient toughness to

avoid brittle fracture while machining. Mechanical properties of the tools are

the results of a compromise between hardness and toughness, depending on the

proportion of binder. Also, diamond deposition encounters some difficulties on

this substrate. First, cobalt is harmful to diamond deposition leading to graphite

formation instead of diamond. Then cobalt must be removed from the surface by

chemical and mechanical treatments before deposition.

Second major

obstacle to diamond deposition is the difference between expansion coefficients

of diamond and carbide tungsten, which induces thermal stresses at the

interface between the two materials. The existence of the interfacial tensile

stresses combine with adhesion problems at the interface lead to premature

failure during machining operations by debonding.

A ceramic coating is silicon dioxide or

silica (SiO2) based. Commonly derived from quartz crystals and sand, silica

creates an invisible, extremely resilient “nanotechnology coating” when

combined with elements like titanium dioxide, polysilazane, triethanolamine,

water, and various other ingredients. Once cured atop a hard surface, this

viscous liquid forms a crystal-clear shell, a product that is referred to as a

nano ceramic coating, or ceramic coating for short.

What are its advantages?

v 1. With

the coating, car requires a very little regular maintenance to keep the

exterior surface of the car look clean and shiny unlike wax coatings that wear

off with regular washing. It’s interesting to know that it requires another

process to remove it completely. Isn’t it a big relief!

v 2. Diamond

withstands repeated car washes without having the swirl marks on your car

surface.

v 3. It

is critical that the car’s gloss fades up and starts looking dull under daily

exposure to sun for long time especially for those who park their cars outside.

The diamond ceramic coatings protect the clear coat from harmful UV rays and

helps retain its gloss and color.

v 4. Ceramic

coating last longer than regular paint and wax coatings. It gives rich and

glossy finish, resist elements like water, dirt and mud from bonding with the

surface and protect the exterior surface of a car.

Drawbacks

Not everything the ceramic coating can do! As a product, it does have some limitations-

v 1. It

does not protect your car from swirl marks and scratches.

v 2. It

is not capable of getting rid from

spots that remain on the car’s surface when the water evaporates from the

surface leaving behind residues of salts and minerals. A regular car wash is

still required for this.

References

https://www.vive-houston.com/blog/ceramic-coating-does-it-work

https://ceramicpro.com/facts-about-ceramic-coating-for-cars/

Ceramic Coating: The Ultimate Car Paint Protection Guide

(avalonking.com)

Ceramic Coating Frequently Asked Questions (ceramicprovancouversw.com)

(PDF) CVD Diamond Coatings for Machining (researchgate.net)

Note: This blog is meant for Educational Purpose only .We do not own any Copyrights related to images and information , all the rights goes to their respective owners . The sole purpose of this blog is to Educate, Inspire, and Empower and to create awareness in the viewers. The usage is non-commercial (Not for Profit) and we do not make any money from it.

Comments

Post a Comment