RECYCLED CONCRETE BLOCKS-ECOFRIENDLY AND COST-EFFECTIVE SOLUTION FOR MASONRY CONSTRUCTION

Introduction:

In this rapidly changing world where every sector is expanding and growing, the construction industry is the second largest industry. It produces around 11% of the GDP through investments. The total Municipal Solid Waste developed by India is around 100,000 Metric Tons. 25% percent of this MSW is produced through construction and demolition. This waste through construction and demolition in towns and cities is through destruction of old buildings and structures, renovations of existing buildings, excavation, construction of new structures, etc.

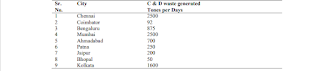

Construction demolition waste

generated in major cities in India

India

produces almost 25-30 MT/year of construction and demolition waste. Of 12

million tons of construction and demolition waste, if 30% is considered as

concrete and 50% is considered as coarse aggregate, the available recyclable

concrete aggregate (RCA) is of the order 1.8 million tons annually. The

remaining waste is dumped in landfills and empty areas. Statistically, there

are only 95 constructed landfill sites in India and around 1285 landfill are

identified. This leads to challenges faced by the environment. Hence,

construction and demolition waste should not be considered unusable and should

be recycled and reused as said by the Central Pollution Control Board,

Government of India.

Present method of recycling and reusing of C&D waste:

Concrete

waste can be reused as cement replacement material in concrete blocks, as fine

aggregate replacement. Mortar production can be done through fine recycled

concrete aggregate. Studies show that 20% of fine aggregate replaced by RCA

show better results. 31% of construction and demolition waste consists of brick

waste. Thus waste clay bricks can be used in mortar and concrete.

METHODOLOGY:

Trial Mix:

The trial mix for producing recycled aggregate concrete, 45

days old concrete blocks are used. Various sizes of aggregates are formed by

crushing concrete blocks and sieving them. Different sieves are used for fine

and coarse form of aggregate.

Tests Conducted on Concrete:

Various tests are conducted on the concrete to test its

strength. The compressive strength, split tensile strength and flexural

strength are tested through different experiments.

Test Results:

Conclusion:

Using recycled concrete aggregate is a unique and

ecologically safe solution. As demolished concrete is available freely the only

economic expenditure will be the transportation and crushing. This is an

environmentally helpful option than the conventional natural aggregate

concrete.

Credits:

Bhakti Gujarathi

S.Y.B.Tech

Manufacturing Science and Engineering

References:

https://www.researchgate.net/publication/344781726

‘Municipal

Solid Waste Annual Report 2014-15’, published by Central Pollution Control

Board, Government of India.

‘Management of Municipal Solid Waste’ status

report published by Central Pollution Control Board, Government of India.

Central Pollution Control Board Bulletin

VOL.-I, JULY 2016

NOTE:

This blog is meant for educational purposes only. We do not own any Copyrights related to images and information, all the rights go to their respective owners. The sole purpose of this blog is to Educate, Inspire, Empower, and create awareness in the viewers. The usage is non-commercial(Not For Profit) and we do not make any money from it.

Write your feedback here:

https://forms.gle/C3ybXMPPUaJBgP618

FOLLOW US ON:

INSTAGRAM :

https://bit.ly/coep_blogs_insta

LINKEDIN:

https://bit.ly/coep_blogs_linkedIn

YOUTUBE:-

https://bit.ly/Coep_blogs_YouTube

Comments

Post a Comment